- START

- NEWS

- SAILING TEAM

- SHOP EN

- SHOP DE

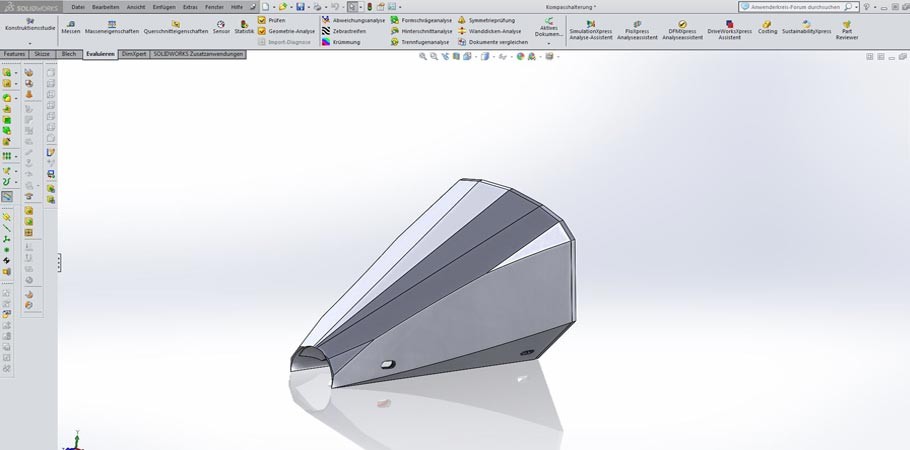

PRODUCTION & QUALITY

carbon composites

MURPHYS is a leading supplier of prototypes and series of fiber composite components. We supply complex 3D designs, prototypes and series in carbon technology.

Production methods:

Autoclave technology, prepreg technology, vacuum technology, RTM technology Carbon forming, 5-axis machining,

Benefit from MURPHYS' experience in the development and production of innovative composite parts.

3 D PRINTING

MURPHYS 3D PRINTED PARTS

Why 3D printing?

PLA, CPE, PETG, nylon, graphene, carbon, PEEK - more and more high-performance objects are coming out of the 3D printer.

Extremely lightweight components, which cannot be produced in this way by conventional means, are becoming a reality. And faster and faster! This is how 3D printing is making its way into

series production.

We can also individualize your products and manufacture them according to your wishes!